Inventory Management in Manufacturing: An Essential Guide

Effective inventory management is paramount for ensuring smooth operations, minimizing costs, and meeting customer demands. Over 30% of organizations have been impacted by incorrect inventory information,1 leading to significant losses and inefficiencies. On the other hand, businesses with optimized inventory management grow revenue 2.5× as fast.1 By implementing proper inventory management, manufacturers can streamline processes and improve overall business success. In this blog, we'll explore manufacturing inventory management strategies, challenges, and best practices to help you optimize your operations.

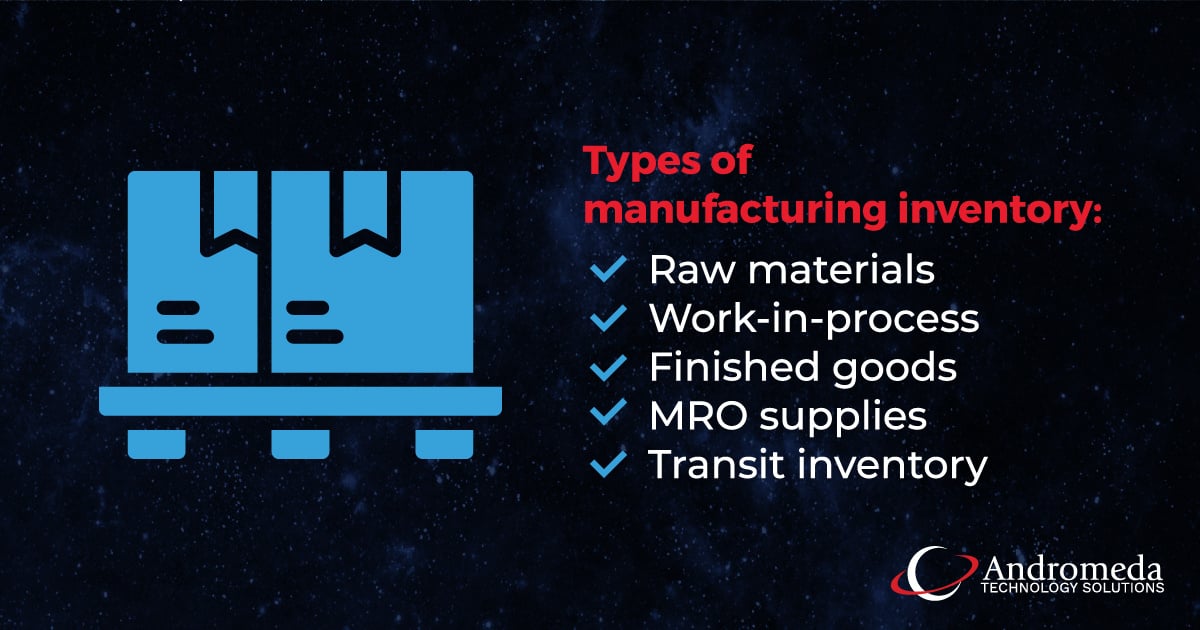

What Is Considered Manufacturing Inventory?

Manufacturing inventory refers to the various components, materials, and finished products involved in the production process. It includes a diverse range of items, and understanding the differences between the various types is crucial for effective inventory management.

Raw Materials Inventory

Raw materials inventory refers to the basic components and materials required to initiate the production process. These can include metals, plastics, fabrics, or any other materials that serve as the foundation for the finished product.

Work-in-Process Inventory

Work-in-process (WIP) inventory includes partially completed products or components that are currently undergoing various stages of the manufacturing process. These items have received some level of processing but are not yet ready for sale or distribution.

Finished Goods Inventory

Finished goods inventory comprises the completed products that have undergone all necessary manufacturing processes and are ready for sale or distribution to customers.

MRO Inventory

MRO (Maintenance, Repair, and Operations) inventory consists of the supplies, tools, and equipment necessary for maintaining and repairing manufacturing equipment and facilities. This inventory plays a critical role in ensuring smooth and uninterrupted operations.

Transit Inventory

Transit inventory, also known as pipeline inventory, refers to goods that are in the process of being shipped from one location to another, such as from a supplier to a manufacturing facility or from a manufacturing plant to a distribution center. This inventory is considered part of the overall supply chain and must be accounted for in inventory management processes.

What Is Inventory Management?

Inventory management is the process of governing the flow of goods and materials throughout the manufacturing process. It involves tracking, monitoring, and optimizing inventory levels to ensure that the right products are available at the right time, in the right quantities, and at the right location.

Why Is Manufacturing Inventory Management Important?

The primary goals of inventory management for manufacturers revolve around maintaining optimal inventory levels, minimizing costs, maximizing production efficiency, and promptly meeting customer demands. A well-designed manufacturing inventory management system helps businesses strike the best balance between having sufficient stock to meet demand and avoiding the pitfalls of overstocking or understocking.

Overstocking can lead to excessive carrying costs, spoilage, and obsolescence, tying up valuable capital that could be better invested elsewhere. On the other hand, understocking can result in lost sales opportunities, dissatisfied customers, and potential damage to the company's reputation. By maintaining optimal inventory levels with proper inventory management, manufacturers can minimize these risks and maximize their profitability.

Some benefits of leveraging manufacturing inventory management software include:

Optimizing Production Efficiency

Inventory tracking can help manufacturers ensure production lines are continuously supplied with the necessary raw materials and components, minimizing disruptions and delays. This seamless flow of materials enables manufacturers to maximize their production capacity and meet customer demands efficiently.

Reducing Costs

An inventory management system can help minimize the carrying costs associated with surplus inventory, such as storage expenses, spoilage, and obsolescence. It also prevents stockouts, which can lead to lost sales, dissatisfied customers, and potential penalties or expedited shipping costs. By reducing stockouts and overstocks, manufacturers can reduce inventory costs by 10%.2

Improving Customer Satisfaction

By consistently meeting customer demand and delivering products on time, manufacturers can enhance customer satisfaction and loyalty, ultimately driving business growth. Reliable delivery and product availability are crucial factors in maintaining long-term customer relationships and a positive brand reputation.

Facilitating Informed Decision-Making

Accurate inventory data enables manufacturers to make informed decisions regarding production planning, forecasting, and resource allocation, ensuring efficient use of resources and maximizing profitability. Real-time visibility into inventory levels and trends allows for proactive decision-making and strategic planning.

Top Manufacturing Inventory Management Strategies

While the goal of inventory management is universal, manufacturers can implement various strategies to achieve optimal results based on factors like product variety, operational complexity, and customer demand. The most common inventory management strategies are:

Perpetual Inventory Management

Perpetual inventory management involves continuously updating inventory records as transactions occur, providing real-time visibility into stock levels. This method is often facilitated by barcode scanning or RFID technology, ensuring accurate and up-to-date inventory data. Perpetual inventory management is particularly beneficial for manufacturers with high-volume operations or those dealing with a large variety of products and components.

Periodic Inventory Management

Periodic inventory management involves physically counting and reconciling inventory at predetermined intervals, such as weekly, monthly, or annually. This method can be suitable for businesses with smaller, less complex inventory operations. However, it can be time-consuming and may result in periods of inaccurate data between physical counts.

Just-in-Time Inventory Management

Just-in-Time (JIT) inventory management is a lean manufacturing strategy that attempts to minimize inventory levels by receiving materials and components only as they are needed for production. This strategy helps reduce carrying costs and storage requirements while ensuring a continuous flow of goods. JIT requires close collaboration with vendors and a highly efficient production process to maintain a smooth flow of materials.

ABC Inventory Management

The ABC inventory management technique categorizes inventory items based on their value and demand. Items are classified as A (high value and demand), B (moderate value and demand), or C (low value and demand). This approach allows manufacturers to focus their efforts and resources on the most critical inventory items. Businesses can optimize their manufacturing inventory management processes and reduce risks like stockouts or overstocking by prioritizing high-value and high-demand items.

Consignment Inventory Management

Consignment inventory management involves manufacturers receiving inventory from suppliers, but ownership is only transferred once the goods are sold. This strategy can help reduce upfront inventory costs and minimize the risk associated with holding excess stock. However, consignment inventory management requires careful tracking and coordination with suppliers to ensure accurate accounting and timely payments.

What Inventory Management Challenges Do Manufacturers Face?

Despite the potential benefits, manufacturers often encounter various challenges when implementing and maintaining inventory management practices. Common challenges include:

Demand Forecasting Inaccuracies

Accurately predicting customer demand can be difficult, leading to either excess inventory or stockouts, both of which can harm profitability and customer satisfaction. Demand forecasting requires sophisticated analysis of historical data, current market trends, and other external factors that can influence consumer behavior.

Supply Chain Disruptions

Unexpected supply chain disruptions, such as delays in receiving raw materials or components, can significantly impact production schedules and inventory levels. These disruptions can arise from natural disasters, transportation issues, or supplier-related problems, making it essential for manufacturers to have contingency plans in place.

Data Inaccuracies

Inaccurate inventory data can lead to poor decision-making, resulting in inefficient resource use, excess inventory, or stockouts. Data inaccuracies can stem from human errors, outdated systems, or a lack of integration between different parts of the supply chain.

Inventory Shrinkage

Inventory shrinkage, which can occur due to theft, damage, or mishandling, can lead to significant financial losses and disrupt production processes. Implementing strict security measures, proper handling protocols, and audits can help mitigate the risk of inventory shrinkage.

Lack of Integration and Visibility

Siloed systems and lack of visibility across different departments or locations can hinder effective inventory management, leading to inefficiencies and miscommunication. Integrating manufacturing inventory management systems with other operations, such as production planning, can provide a holistic view and facilitate better decision-making.

Tips for Manufacturing Inventory Management

Consider implementing the following best practices can help you overcome these challenges and maximize the advantages of manufacturing inventory management:

Invest in Inventory Management Software

Inventory management software can help manufacturers streamline operations, reduce manual errors, and improve overall efficiency. Implementing the right manufacturing inventory management system provides real-time visibility into stock levels, automates processes, and facilitates data-driven decision-making.

Optimize Inventory Levels

Regularly review and optimize inventory levels to ensure you can both meet customer demand and minimize inventory costs. Techniques like safety stock and reorder points can help achieve this. Continuously monitoring inventory levels and adjusting them based on demand patterns can help manufacturers avoid overstocking or stockouts.

Improve Demand Forecasting

Accurate demand forecasting can help manufacturers anticipate changes in customer behavior and adjust their production and inventory strategies accordingly. Leverage historical data, market trends, and advanced analytics from inventory management software to improve demand forecasting accuracy and ensure inventory levels align with customer needs.

Streamline Operational Processes

Continuously evaluate and streamline processes to identify and eliminate inefficiencies, reducing waste and improving overall operational efficiency. This may involve implementing lean manufacturing principles, automating manual tasks, or redesigning workflows to optimize resource utilization.

Foster Supplier Collaboration

Collaborate with your suppliers to ensure a seamless flow of materials and components, mitigating supply chain disruptions and facilitating better inventory planning. Strong supplier relationships, clear communication, and aligned goals can help manufacturers maintain a consistent supply of raw materials and reduce stockouts or production delays.

Manufacturing Inventory Management FAQs

Below, we answer some frequently asked questions about manufacturing inventory management:

What is inventory management?

Inventory management refers to the processes and practices involved in overseeing and controlling goods and materials throughout the manufacturing process. It encompasses tracking, monitoring, and optimizing inventory levels to ensure that the right products are available at the right time, in the right quantities, and at the right location.

What is the purpose of inventory management?

The primary purpose of manufacturing inventory management is to maintain optimal inventory levels for minimized costs and maximize production efficiency and customer satisfaction. Effective inventory management aims to strike the perfect balance between having sufficient stock to meet demand while avoiding the pitfalls of overstocking or understocking, both of which can be detrimental to a company's financial health and operations.

What are the main inventory planning strategies?

Manufacturers can implement various inventory management strategies to achieve optimal results, including perpetual inventory management, periodic inventory management, just-in-time (JIT) inventory management, ABC inventory management, and consignment inventory management. The choice of inventory management strategy depends on factors such as your operational requirements, product variety, and the complexity of inventory operations.

How does inventory management affect end customers?

Inventory management systems play a significant role in enhancing customer satisfaction and loyalty. By consistently meeting customer demand and delivering products on time, manufacturers can foster long-term customer relationships and maintain a positive brand reputation. Additionally, accurate manufacturing inventory software enables businesses to make informed decisions regarding production planning, forecasting, and resource allocation, ensuring timely and reliable delivery to customers.

Streamline Your Manufacturing Inventory Management With Andromeda

Implementing an inventory management system can help manufacturers gain a significant competitive advantage by optimizing inventory levels, reducing waste, and meeting customer demands. However, selecting and maintaining the right inventory management strategy can be difficult, particularly if you're not sure where to get started.

At Andromeda, we understand the unique challenges faced by manufacturers and offer tailored technology solutions to streamline your manufacturing processes. Our team of experts can keep your operations running smoothly with services and support that solve your unique challenges – so you can focus on growing your manufacturing business instead.

Book a meeting today and discover how Andromeda can empower your operations with IT solutions designed for the manufacturing industry.

Sources:

- https://gitnux.org/inventory-management-statistics/

- https://www.netstock.com/blog/the-ultimate-list-of-inventory-management-statistics/

Keep Your Business Safe, Secure, and Running

We’ll take a proactive approach to your manufacturing IT – and help your business blast off.